In order to uncover the potential in the service, maintenance and repair of equipment, devices, machines, plants and much more, an increasing number of manufacturers, service partners and also operators are using the so-called Equipment Lifecycle Analysis as a tool. In this blog article, we explain what is meant by the term, why Equipment Lifecycle Analysis is needed and how it works.

What is an equipment or asset?

In the industrial context, the term refers to “property, plant and equipment”, thus tangible assets. This also includes, for example, machinery, equipment, vehicles or buildings.

What is an Equipment Lifecycle?

An Equipment Lifecycle describes the sequence of phases in the lifecycle of a particular equipment. The lifecycle usually begins with planning, in which the need for a particular equipment is first determined, and continues throughout the equipment’s useful life until it is disposed of. Between planning and disposal, the equipment usually passes through the phases of engineering, procurement, commissioning, operation and replacement, sometimes also upgrade, retrofit or overhaul. In the context of industrial, plant-related equipment or asset management, the Association of German Engineers (VDI), for example, only considers the longest and most important part of the Equipment Lifecycle in its underlying definition: operation and maintenance. In this article, we also focus on operation and maintenance.

What is an Equipment Lifecycle Analysis?

An Equipment Lifecycle Analysis describes an analysis within the Anything-Relationship-Management (XRM), in which the complete lifecycle of a equipment or product is mapped and subsequently examined for optimization potential. In the following, you will learn what is important in the preparation and which factors must be taken into account in addition to the individual lifecycle stages of industrial machinery and equipment.

Why conduct an Equipment Lifecycle Analysis?

The Equipment Lifecycle Analysis is intended to help stakeholders of a company to uncover the potential for improvement along the lifecycle of, for example, a machine or plant. These findings must be taken into account during implementation, for example in the course of the company’s digital transformation. It is essential for successful manufacturers to have knowledge about the availability, use and quality of their own assets.

An Equipment Lifecycle Analysis can be performed as shown below:

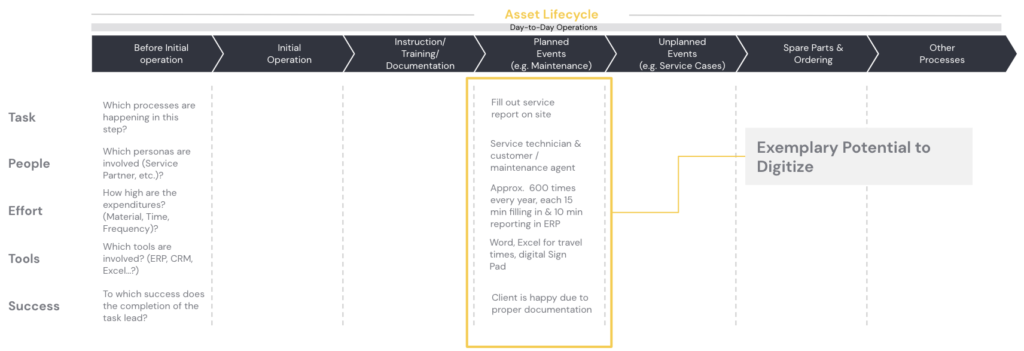

The Equipment Lifecycle is first visualized as a linear progression. To do this, you mentally walk along the entire lifecycle of an equipment and graphically display it on the basis of two dimensions in a so-called Equipment Lifecycle Matrix.

The horizontal Axis

From left to right, all stations that an equipment passes through during its lifecycle are mapped here. This cycle begins even before the actual commissioning, includes e.g. planned and unplanned events as well as spare and wear parts and usually ends with the disposal or replacement of the equipment. The following applies to each step: The more precise the description and delimitation to the previous step, the more detailed and meaningful the subsequent analysis will be.

The vertical Axis

The vertical axis represents the levels of analysis. First of all, it is important to precisely describe the tasks that arise for each step. This gives an overview of the people and tools that are involved in each step. In addition, the effort as well as the success are considered and contrasted.

Every Equipment Lifecycle is unique

Each Equipment Lifecycle Analysis is tailored to a specific equipment or equipment type. Here, it is important to understand the functionality and needs of an Equipment Lifecycle and to perform the analysis for a specific equipment type. For example, the steps of the Lifecycle Analysis of one equipment may not be useful for another one.

This therefore means that a company with for example several machine types or plants cannot necessarily operate with one universal Equipment Lifecycle Analysis, but might need to create it individually for every equipment (type). In return, you benefit from a 360-degree overview of your installed base, which then subsequently forms the basis for deriving the digitization potential. Nevertheless, in our experience, in most cases it is sufficient to create one well-founded Equipment Lifecycle Analysis which then serves as a basis to record the differences within the Equipment Lifecycle Matrix for the different equipment types. In the end, similar IT-Systems and people are often involved when it comes to service, maintenance and repair of different equipments.

How is an Equipment Lifecycle Analysis created?

Before you start to analyse your Equipment Lifecycle, it is important to answer a few questions:

- Who is the analysis being created for? In the field of industrial machines and equipment, for example, this persona would be the service or maintenance manager.

- What type of equipment is displayed? There is a wide range and variety of different equipments in the industry. It is therefore important to classify the equipment precisely in order to be able to analyse it efficiently later. Naturally, the lifecycle of a certain machine looks different from that of a building.

- What findings should be derived from this? Which goals should be achieved? This question, like the equipment itself, is also very individual and varies from company to company. In general, the goal of an Equipment Lifecycle Analysis is to gain a precise understanding of the processes today and the potential of tomorrow. For service managers in the machine manufacturing industry, in addition to increasing efficiency or sales, classic goals include strengthening customer loyalty along the lifecycle in after-sales. Maintenance managers on the other hand, in addition to increasing efficiency, often strive for extending the lifetime of the equipment or minimizing downtimes.

Once you have an answer to these questions, you can start working on the Equipment Lifecycle Analysis.

Step 1 – Put the Equipment Lifecycle Analysis team together

Even if not every employee has a direct point of contact with the equipment, different departments should be represented in the analysis team.

- For manufacturers and service partners: e.g. internal service, field service, management, IT, etc.

- For operators: e.g. maintenance teams, maintenance agents, machine operators, etc.

Even employees without direct equipment contact can provide valuable insights and new perspectives. They are also getting sensitized to keep the equipment in mind at every step of the process. These parties should definitely be involved:

- Service managers: Can provide an equipment-centric assessment and have in-depth knowledge of the installed base

- Service technicians: can make concrete and practical statements about the needs and requirements of the equipment by working directly with it

- IT: can provide additional input on possibilities and limitations of data availability and analysis

- External consultants/coaches: In some cases, they help to bring in an external perspective that resolves the so-called operational blindness and thus contributes new insights

Step 2: Draft – Create the first draft of the Equipment Lifecycle

The analysis team should then meet in e.g. a workshop to develop a first draft towards the Equipment Lifecycle. We recommend appointing a mediator to ask the questions and note down the team’s answers. What steps does the asset go through along its lifecycle from before it is put into operation until the end of its lifecycle? Which parties, organizations, people, IT systems and processes are involved?

This step is about the first, rough draft. Not too much time and resources should be invested here; a 2-3 hour kick-off workshop with the analysis team should be sufficient. The focus should rather be on the development of a common roadmap. This can also be reflected in the form of presentation, the use of flipcharts and post-its is recommended here.

Step 3: Collect data – Back up assumptions with facts

After the brainstorming, the analysis continues with the “Hard Facts”. Here the aim is to back up the previously discussed sub-steps and processes with data, facts and figures. Be as precise as possible. How often does the service technician fill out the service report each year, how long does it take every time and who processes it? Are the reports still paper-based, or do they have to be printed out from Excel or Word on-site, then signed, scanned in again and transferred manually from the back office to the ERP system? Measure the time end-to-end for a representative service case. This work may seem to be time-consuming and demanding at first, but it also enables you to pinpoint in detail where the service can be optimised with the help of digitisation.

Data sources can be internal or external, experience reports from service partners can be just as helpful as data from your own colleagues in the service field or from the maintenance team.

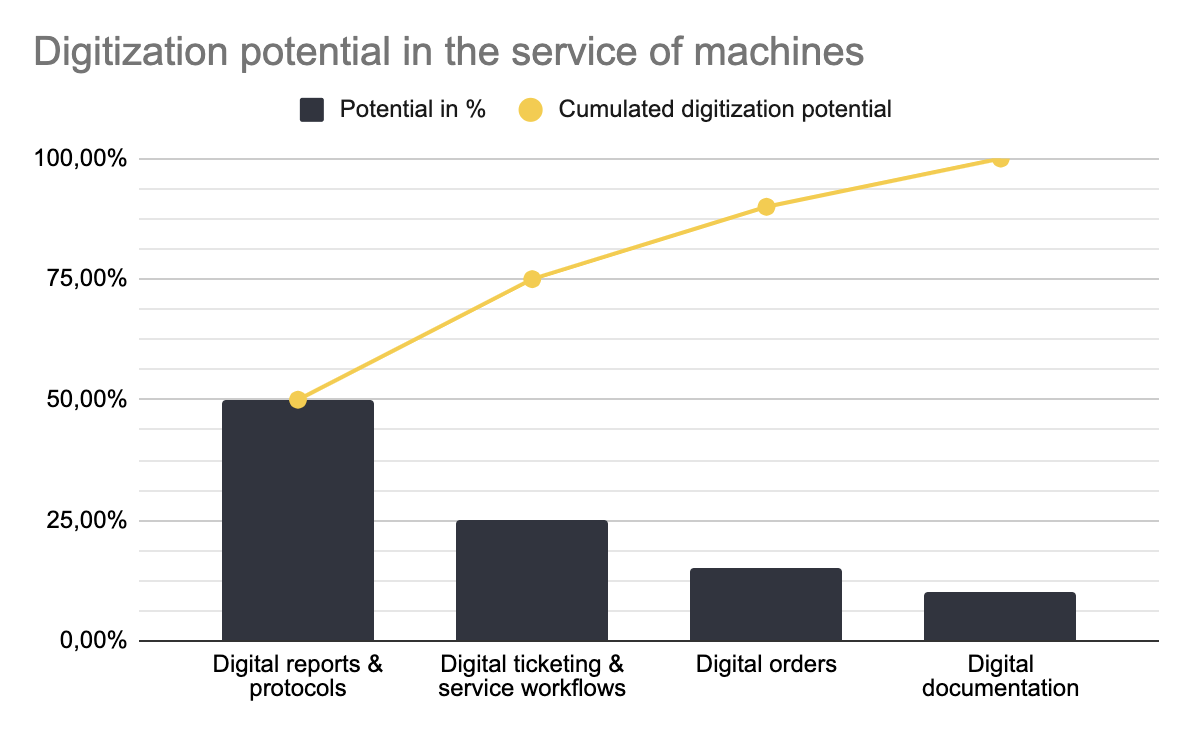

Step 4: Pareto principle – identify and prioritize the most important potential

The Pareto principle states that in many cases an 80 percent result can be achieved with only 20 percent of effort. This principle is also applied to the digitization and optimization potential in industrial service. Here, it is helpful to enter the potential in order of importance as columns in a two-dimensional coordinate system (Pareto diagram). This serves as a basis for decision-making, enabling you to differentiate between important and unimportant potential. Having done this, you will be able to prioritize the order in which you approach the potential with a clear course of action. The more profoundly the Equipment Lifecycle has been filled out and structured in the previous steps, the easier it is in this step to identify sticking points and derive the corresponding actions. The aim here is to analyze the Equipment Lifecycle Matrix and examine it for anomalies or repetitive, low-value tasks. For which of the activities that occur along an Asset Lifecycle can you relieve your employees or offer additional services to your customers? Which processes, that today still mean manual effort for your employees, can you optimize and what can a solution look like?

In our experience, companies that are not yet as advanced in terms of digitization and servitization in particular have a lot of potential for increasing efficiency. It is precisely this potential that is made visible and tangible with the Equipment Lifecycle Analysis.

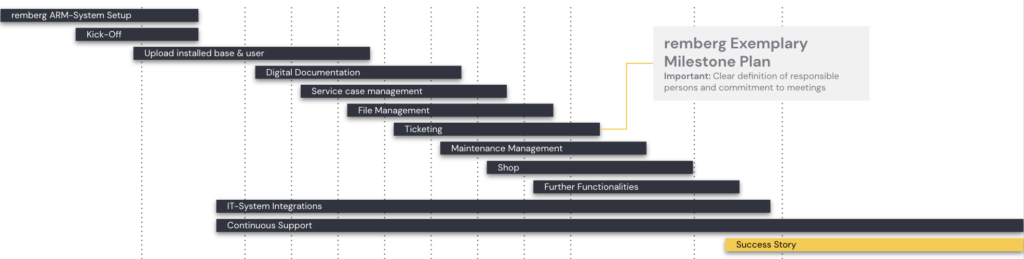

Step 5: Roadmap to realize the potential in service

For implementation, we recommend preparing a clear roadmap based on the potential and assigning internal and external responsibilities to the respective parties.

Here we recommend to put together a “speedboat” within the organization, similar to the analysis team. This means that it is useful to assign a project manager, in the best case scenario with a background in the service or maintenance department. Our experience showed that only in a few cases is it actually successful to realize the potential in the service department, if the responsibility lies in the IT or the digitization department, because the right incentive from the daily business is often missing. You should check whether the resources required for implementation are already available internally or whether you want or need to work with external providers. In both cases, you should make sure that the necessary know-how in the field of industrial assets or service or maintenance is available on the IT side. It is also important that your top management provides the necessary support for the implementation process.

You want to get started with the Equipment Lifecycle Analysis? We would be happy to show you how we are already helping other companies today with our XRM software and how we can also help you to improve the service, maintenance and repair of your equipment according to the Pareto principle.

Back

Back